by Sam Franklin | June 27, 2022 | 10 min read

All there is to know about shipping with reefer containers

Get fundedLast updated: July 08, 2022

If you are looking to ship fruits, meat, flowers, seafood, pharmaceutical products or any other goods that need to be in a temperature-controlled environment, you need a reefer container. A reefer or a refrigerated container keeps your goods fresh for longer and extends their shelf life. These containers help maintain the quality of your products, especially when they are transported across long distances.

In this article, we talk about what reefer containers are, why you may need them, the different types, and how they work.

Table of Contents

- What is a reefer container?

- Composition of a reefer unit

- What can I ship in a reefer container?

- How does a reefer container work?

- Reefer container types

- What is the capacity of a refrigerated container?

- How to stow cargo in reefer shipping containers

- Before shipping

- Stowing

- Reefer stowage dos and don’ts

- Advantages of using reefer containers:

- Disadvantages of reefer shipping containers

- 2. Lack of enough reefers for LTL

- How much does it cost to ship in a reefer container?

- FAQ

- What is a non-operating reefer container?

- What are gensets for refrigerated containers?

What is a reefer container?

Reefer containers are essentially refrigerated containers. These look a lot like regular shipping containers but they have three differentiating features. Refrigerated containers can maintain a stable temperature inside. They have controlled humidity levels and adequate airflow. These are also designed differently compared to regular dry containers. These features will help keep perishable goods pristine, protecting them from spoilage due to heat, excessive cold, lack of adequate airflow, or too much humidity.

Reefer containers keep things fresh by removing heat that is generated by the respiration of products. To understand how products respire, let's take an example of fruits. There are two types of fruits: The first type continue to ripen after they are harvested, and in the process, they respire or convert oxygen and sugars into carbon dioxide, water, and heat. These are called climacteric fruits, like mangoes, pears, and bananas.

The second type is non-climacteric. These stop ripening after they are harvested. Non-climacteric fruits include grapes, strawberries, raspberries, watermelon, and cherries.

Composition of a reefer unit

A reefer container has a controller unit at the front that adjusts the temperature, ventilation, and humidity settings for specific cargo types. A refrigerated container is fitted with a power plug cable that can be plugged into a vessel, a terminal, or the genset on a truck. These usually maintain a temperature range of -20 to 30 degrees Celsius, making them suitable for commodities that need to be shipped in a temperature-controlled environment.

Reefer units’ air exchange system helps maintain optimal oxygen levels keeping the products fresh, whereas the dehumidification feature keeps the environment inside the container dry.

Here are the main components of a reefer container:

Genset: A reefer unit's power source, a generator set is usually dual-powered, which means it can run on fuel or the power unit on a ship. These can be both clip-on (clipped to the side of the container) or underslung (placed on the chassis of a truck or a container).

Humidity control: This is an important part of a refrigerated shipping container as it ensures optimum humidity conditions for perishables, electronics, or pharmaceutical products.

Air temperature control: Reefers containers are mostly air-cooled, although they can also be water-cooled. Reefer containers have air cooler fans to remove dissipated heat, a compressor unit, a condenser that cools the air, and an evaporator to keep the cargo dry.

What can I ship in a reefer container?

Here are the main kinds of commodities that can be shipped in a reefer container:

Frozen: The frozen category includes goods that need to be kept at -5 degrees celsius or in a low air temperature environment during shipping. These mainly include ice cream, concentrates, meat products like poultry and pork, frozen seafood like salmon and tuna, and beef.

Chilled: Chilled products need to be shipped in temperatures over -5 degrees. These need to be in low temperatures but don’t need to be frozen. Chilled products include dairy, eggs, confectionery, and fruits and vegetables. These products are extremely temperature-sensitive.

Miscellaneous products: Other temperature-sensitive products include pharmaceuticals, batteries, chemicals, and tobacco. These need to be shipped in a refrigerated container as well.

Read more about freight transport and container shipping.

How does a reefer container work?

The air inside refrigerated containers is circulated by two fans. The air is first pushed down and enters the container space through the T-bar floor. Reefer containers have aluminium T-bar floors that are specifically designed to facilitate air circulation, which is essential for maintaining cargo temperature. The air passes through the cargo and keeps the temperature at a steady level. The air is then pushed by propellers through the cooling engine again, and the whole process repeats. This constant movement of air keeps products fresh.

Reefer container types

There are three main types of reefer units in use:

1. Closed reefer

The most commonly used reefer container, a closed reefer, has an integral front wall and an integrated heating and cooling unit.

2. Modified/Controlled Atmosphere (MA/CA)

These container units have enhanced insulation compared to closed reefers. The MA/CA reefer container can maintain a consistent interior environment throughout the shipping journey.

3. Automatic Fresh Air Management Containers (AFAM)

These are highly sophisticated reefer containers that use various sensors to adjust the fresh air exchange rate. Like MA/CA reefers, AFAM reefer containers also maintain precise oxygen and carbon dioxide levels and help extend the products’ shelf life.

What is the capacity of a refrigerated container?

You can find reefer containers in varying sizes, dimensions, and capacities. Here are some common ones:

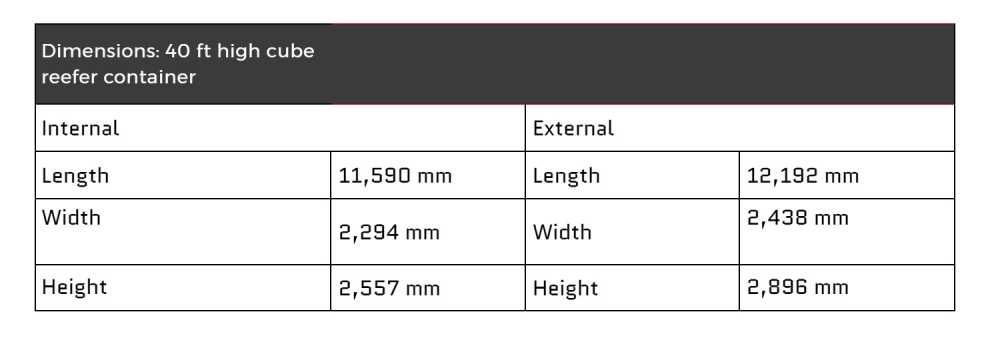

40 ft high cube reefer container

These are about 30 cm higher compared to regular 40 ft reefer containers. 40 ft high cube reefer containers are ideal for shipping and storing goods that need a temperature-controlled environment.

Capacity: Maximum load: 30,420 kg Maximum weight: 35,000 kg Tare: 4,140 kg

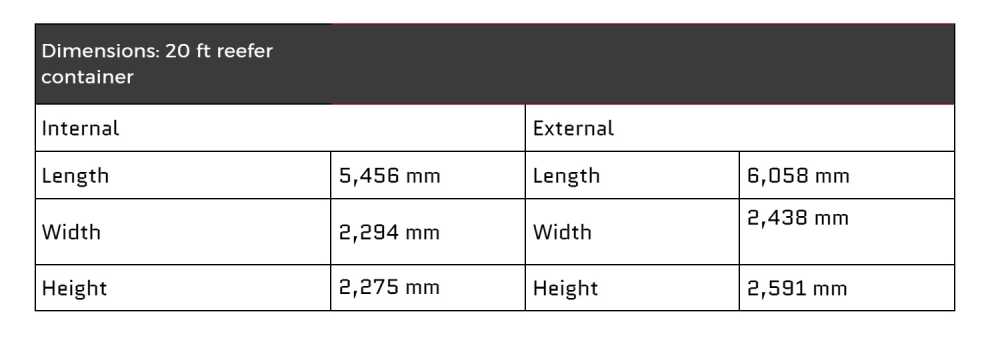

20 ft reefer container

Capacity:

Maximum load: 30,480 kg Maximum weight: 2,7540 kg Tare: 2,500 kg

How to stow cargo in reefer shipping containers

Reefer containers will keep your products fresh and in the best shape, but you need to follow some basic precautions as well. Cargo for reefer containers has to be handled sensitively throughout the transportation and stowing process. Here are some tips to follow while handling reefer cargo at different stages of transportation and stowing:

Before shipping

Document your reefer cargo down to the last detail and provide only the most accurate information to shippers or freight forwarders. They should have all the information regarding the shipment's contents, including the accurate volume, weight, temperature, and humidity requirement, pallet or box type, and any other specifications needed for handling. These are essential for shipping in reefer containers so that your goods are handled in the most appropriate way.

Stowing

Before you stow your products, they need to be packed in a way that they are not damaged by rough handling. You also need to pick the right packaging material to keep your goods from spoilage by humidity or harmful bacteria. The packaging should also be strong enough for stacking. Different types of goods have different stowing requirements. For example, frozen goods have to be stacked without any gaps, while chilled goods need space for airflow. Here are some things to remember while stowing:

Reefer containers have red load lines near the ceiling and the door. These should be meticulously followed so that there is enough space for free and adequate airflow.

Cover the entire floor of the reefer with cargo. This will ensure that the airflow inside the container is even.

Make sure that the reefer container is clean and dry before it is loaded. Any moisture or humidity in the container can lead to mould or bacteria and damage your goods.

Goods that need to be shipped at a low temperature should be pre-cooled. The sooner the commodities are cooled after harvesting, the longer their shelf life will be.

The reefer unit should not be pre-cooled. This is because when the cool air from inside and warm air from outside meet, it can cause condensation and humidity, which is bad for your goods.

Chilled cargo needs a constant free flow of air to remove the heat and respiration gases. Therefore, it has to be placed in a way that facilitates a free flow of air. Your choice of pallets and packaging material should also facilitate symmetrical airflow.

Frozen cargo requires air circulation around the entire load. This means that you can’t leave gaps in between the products.

Reefer stowage dos and don’ts

Here are the do's and don'ts of reefer stowage:

Dos:

Set the reefer at specific temperature and humidity settings required for your goods.

Pre-cool the cargo

Don'ts:

Respect the loading space and don’t stow your products above the load line.

Don’t stuff your products too tightly that they block airflow.

Don't pre-cool the reefer.

Don't leave gaps between pallets and the door.

Advantages of using reefer containers:

Here are the main advantages of reefer units:

A refrigerated container helps extend the shelf life of products.

These can be divided to create different segments for frozen and chilled goods with the same container. Different segments can have different temperature settings too.

Refrigerated containers are available in a variety of sizes and different external and internal dimensions, which can be used for shipping perishable cargo, pharmaceuticals and other products over land or sea.

Reefer containers can be easily used in harsh weather environments.

These offer a better return on investment than reefer ships as they can be shipped on different types of carriers across land and sea.

Refrigerated containers can skip cold storage on arrival at the destination port.

A reefer container is easy to load and unload.

Disadvantages of reefer shipping containers

Here are the main disadvantages of refrigerated units:

1. Failure of equipment

Reefer units can experience sudden problems or malfunction due to fluid leaks, faulty belts or faulty calibration, issues with door seals, some kind of a blockage, or damaged air chutes. These problems need to be addressed quickly before the temperature in the reefer is affected, and the products inside start to spoil or rot. The best way to avoid these is to ensure that your shipper conducts regular maintenance checks.

2. Lack of enough reefers for LTL

It is hard to find reefers for less than truckload (LTL) freight shipping because you need to find goods that need the same temperature and humidity range which are also going to the same location as your products. This means you may spend more money on LTL shipping for reefer cargo.

How much does it cost to ship in a reefer container?

Post pandemic, there has been a sharp rise in reefer freight rates. There has also been a lack of availability of reefer containers during this time. From the U.S. West Coast to the far East, the average rate for 12-month contracts running from the second quarter of 2022 to the end of first quarter of 2023 is $5,945 for a 40’ reefer, a jump of almost 60% compared to the 12-month contracts which ended on 31 March 2021.

Some experts suggest that you may save costs in the long run by buying a reefer container if you regularly ship temperature-sensitive goods. This will also save you the hassle of looking for a container every time or negotiating prices. If you don't want to buy one, you can also lease it.

FAQ

What is a non-operating reefer container?

Non-operating reefers are shipping containers with refrigeration units that are turned off. These can be used to stock goods that are usually placed in a dry container. Shipping companies use these as dry boxes instead of leaving them idle or sending them back to the origin as empty containers because of a lack of demand.

What are gensets for refrigerated containers?

Gensets or generator sets are essential for a reefer container. These are used when regular shore power supply is not available for reefers. A reefer container needs a constant supply of power and gensets ensure that there are no interruptions in cooling and your goods are not spoiled.

Written by

Sam founded his first startup back in 2010 and has since been building startups in the Content Marketing, SEO, eCommerce and SaaS verticals. Sam is a generalist with deep knowledge of lead generation and scaling acquisition and sales.