by Sam Franklin | October 06, 2022 | 16 min read

What exactly goes into fulfilment costs, and how do I keep them as low as possible?

Get fundedLast updated: October 07, 2022

Retailers that operate online often have to consider fulfilment costs as one of their main expenses. This is especially true for eCommerce companies, which have to factor in the cost of shipping, inventory, storage, packaging, returns, and more. While keeping these items low is important, you don't want to ruin the product quality and customer experience in the process.

Most eCommerce businesses don't realise how much they can save by taking certain steps to streamline their fulfilment. According to Metapack's Delivery Benchmark Report, 77% of shoppers want cheap or free delivery, speed (e.g. same/next day delivery), or convenience of delivery (location, time slot). We'll show you what exactly goes into fulfilment costs and some recommendations to implement to cut your costs without cutting corners.

Table of contents

- What are order fulfilment costs, and how do they work?

- Breakdown of common fulfilment costs and average pricing

- How to calculate fulfilment costs

- Is outsourcing fulfilment costs worth it?

- The impact of NOT having an effective fulfilment system

- Tips for cutting fulfilment costs while maintaining quality

- Considerations when comparing 3PL fulfilment costs

- Fund the fulfilment of your online shop with Bloom

What are order fulfilment costs, and how do they work?

Fulfilment costs are the expenses associated with getting a product from the supplier to the customer. This includes the cost of receiving, processing, storing, and shipping orders. These costs may vary depending on the order size, complexity, pricing model, and fulfilment providers, but they typically include labour, packaging, and transportation items.

While order fulfilment costs may seem like a small part of doing business, they significantly impact your bottom line in terms of customer experience and profit margins.

For example, if your fulfilment process is inefficient, it can lead to higher labour costs and longer shipping times. Businesses often outsource their order fulfilment to a third-party logistics provider (3PL) to reduce these costs. 3PLs tend to have access to lower-cost shipping and can often provide other value-added services, such as returns and call centre support.

Breakdown of common fulfilment costs and average pricing

When running an eCommerce business, one of your top priorities is getting orders to your customers as quickly and efficiently as possible. To do that, you need a good order fulfilment partner. But what does a good order fulfilment partner cost?

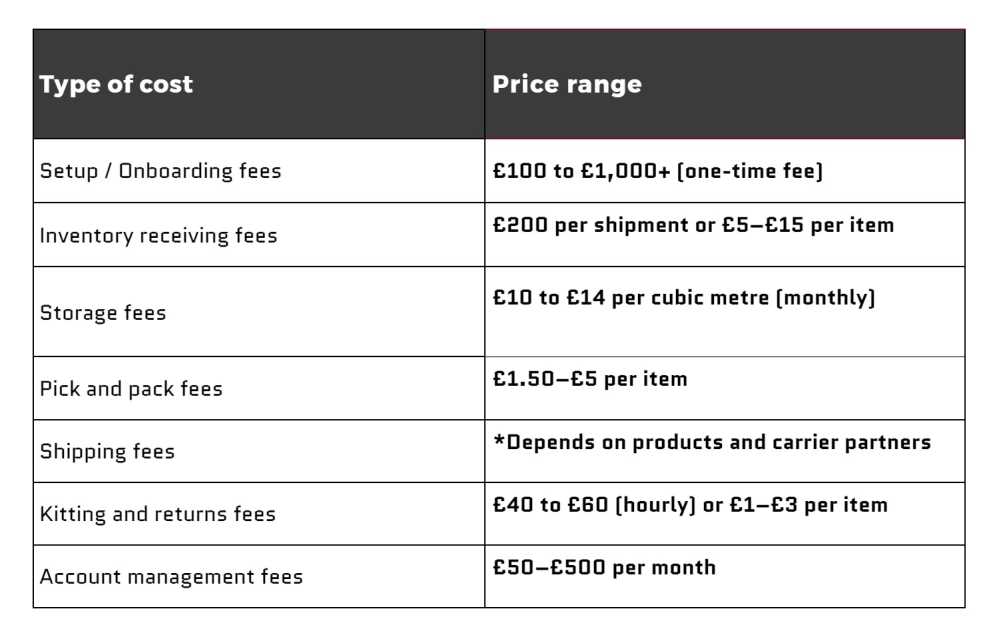

Let's break down the standard order fulfilment charges to answer that question. Generally speaking, there are seven main types of costs associated with this:

1. Setup fees

Also known as onboarding costs, these are one-time charges often based on the type of business and volume you expect to fulfil. It covers the cost of getting a new fulfilment centre up and running, meaning integrating fulfilment software, creating infrastructure, handling your goods, and offering training on the fulfilment provider resources. Some 3PLs offer this initial setup for free, while others can charge you hundreds to thousands of pounds.

2. Inbound shipping and inventory receiving fees

You'll likely incur inbound shipping and inventory receiving charges when shipping inventory from your manufacturer or warehouse to your fulfilment centre. These are fees levied by the fulfilment company for the process of receiving, processing, and inspecting your inventory.

Both of these fulfilment costs are based on the weight and dimensions of your shipment, the number of products you have in stock, and the facility storage capacity. You can expect to pay around £20–£50 per hour, or £5–£15 per item or unit basis (e.g. pallet).

3. Storage fees

Most 3PL storage rates are dictated by elements such as the nature of the item itself, the volume of space needed for proper care of the goods, climate control, extra security, and – a not-so-common one – peak seasons. Whether it's a pallet, a square foot, or a square metre, eCommerce businesses pay a flat rate for the total amount of space their inventory will occupy for a given period. For reference, on average, each pallet ranges from £5–£40 per month.

4. Pick and pack fees

'Fulfilment charges' are the costs assessed by your fulfilment centre for picking from storage and packing your orders for shipment. These fees are roughly £2–£5 per order, depending on the company. Some services offer bulk rates for shipping multiple items at the same time, but others may add an additional small fee. In addition, pick and pack fees may be quoted on a per-order or per-shipment basis.

5. Shipping fees

Whether by air, sea, or land, outbound shipping rates are the ones that cover the delivery of an item to the shopper once it leaves the fulfilment centre. Exact prices are set according to the method of transportation and the size, weight, and destination of the goods. The vast majority of fulfilment services take care of shipments and may even offer you a discount of 10%–30% for high volume orders, but some merchants prefer to use their own carriers.

6. Kitting and return fees

Why two fees in one? Because although the kitting fees only cover the assembly of the items before fulfilment, these fees may also apply to returned items. That's why. And return fees, on the other hand, are quite simple to understand. If the product is damaged or doesn't work as it should, the return fee includes re-receiving and dealing with the faulty items.

These costs of £1–£3 normally cover handling the item, inspecting returned items for problems, reconditioning if necessary and restocking to ensure everything is ready for resale. Depending on the company, kitting and return might be included under the Pick and Pack fees.

7. Account management fees

Last but not least, account management fees are that portion of your monthly fulfilment bill that goes towards keeping your account running smoothly. This can range from administrative costs such as customer service, communication with suppliers, software updates, inventory reports, and pretty much any other situation related to fulfilling orders. Values are around £50–£500.

How to calculate fulfilment costs

Any successful eCommerce business understands that happy customers are the key to long-term growth. Part of the satisfied customer equation is ensuring that orders are fulfilled quickly and accurately. A late or incorrect order can result in a frustrated customer, so it's important to calculate fulfilment costs to ensure that your online shop is running the way it should.

To calculate fulfilment costs, proceed as follows:

Choose at least one of the best fulfilment companies in the UK.

Go to the Pricing page on their website and continue to the next step.

If visible, write down the fulfilment fees (based on item, unit, etc.).

List the number of pallets, orders and/or units per order for a period of time.

Determine the subtotals for each line item (e.g. 15 large parcels x fee per item).

Add up all subtotal charges to come up with an estimate of fulfilment costs.

For example, with Huboo, we can estimate that if each Large Parcel to 10kg is £6.63–£7.19, and we need 15 large parcels for our hypothetical eCommerce, then the maths would end up being something between £99.45 or £107.85. Of course, other components – such as the ones we already discussed in the breakdown of common fulfilment costs – must be included.

Tip: Add 10% more room to your rough estimate to mitigate inaccuracies.

What if you have no idea how many pallets, orders or units you need? In that case, get in touch with the fulfilment company and ask them so they can better assess your requirements. The more detailed the numbers, the more precise the estimate will be.

Now, when comparing rates or analysing fulfilment efficiency, don't miss the following metrics.

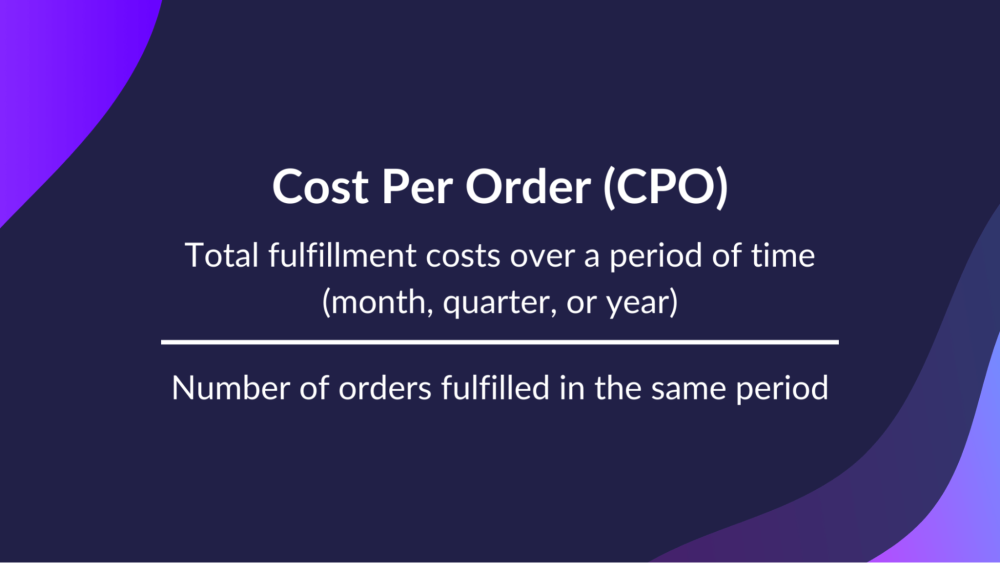

Cost Per Order (CPO)

Cost Per Order, or CPO, is a metric that represents the total fulfilment costs within a certain time period (i.e., one month, quarter, or year) divided by the number of orders fulfilled during that same period. In other words, it tells you how much it costs to fulfil an order, on average.

For example, £15,000 fulfilment costs (month) / 1,000 orders fulfilled = £15 CPO.

This information helps online retailers understand their fulfilment costs and identify areas where they can improve their operations and cut costs. If the CPO for a particular time period is higher than usual, this may indicate that the eCommerce business is incurring extra costs.

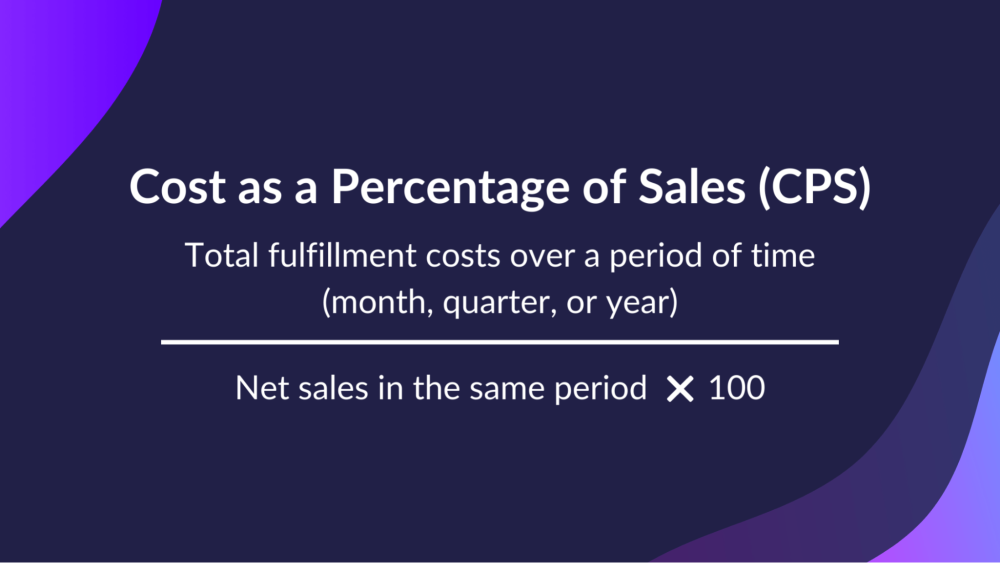

Cost as a Percentage of Sales (CPS)

Cost as a Percentage of Sales (CPS) is a metric that shows you what percentage of your sales is being eaten up by costs and, therefore, how much profit you're making. A high CPS could mean you're not generating much profit, while a low CPS means you're doing quite well.

To calculate CPS, simply divide total fulfilment costs by net sales and then multiply by 100.

For example, if your company had £100,000 in sales last month and £15,000 in total fulfilment costs, your CPS would be 15% (£15,000 ÷ £100,000 ✕ 100). And again, this is very useful for comparing the relative efficiency of different time periods.

Keep in mind that CPS will vary over time, depending on changes in the cost of goods sold or seasonal fluctuations in sales. It's normal. What's important is that if you notice a dramatic increase in CPS, say over 25%, that's something that must be tackled promptly.

Is outsourcing fulfilment costs worth it?

Fulfilling orders is one of the most essential—and expensive—aspects of running an online shop. But what many eCommerce owners don't realise is that there are times when outsourcing fulfilment can actually save resources and give the flexibility to meet customer demand.

Here are three scenarios when it's worth outsourcing fulfilment:

When you're experiencing rapid growth. If your business grows faster than you can handle, it might be time to outsource fulfilment to a third-party logistics (3PL) provider. 3PLs have the infrastructure and resources to keep up with your growing business. And they often have better rates than shipping carriers.

When you're launching a new product. Launching a new product always represents some risk—you never know how well it will do or how much inventory you'll need. Outsourcing fulfilment helps minimise that risk by giving you the flexibility to increase or decrease order volume as needed.

When you need specialised expertise. If you're selling a complex product that requires special packaging or shipping considerations, it might be worth outsourcing fulfilment to a company that specialises in that type of product. They'll be able to ensure that your items are packed and shipped correctly, saving you time and money in the long run.

The impact of NOT having an effective fulfilment system

It's no secret that without good fulfilment, your business will suffer from lost sales, decreased customer satisfaction, increased shipping costs, and more. If you're not sure whether or not your fulfilment process is up to par, these are a couple of signs that it might be time for an upgrade:

You're constantly dealing with all kinds of errors, mistakes and lack of infrastructure.

Your customers are frequently complaining about late or missing orders.

It's taking longer and longer to fulfil orders, and that's the only thing you do.

You're spending more and more money on shipping and missing bulk discounts.

There's no integrated automation technology to keep up with the pace of growth.

If you see any of these signs, it's time to reevaluate your fulfilment system. Otherwise, you risk losing customers and sales – not to mention putting a strain on your staff. Luckily, improving your fulfilment is possible. By streamlining processes, investing in new technology, and partnering with the right fulfilment provider, you'll get your eCommerce back on track and scale.

Tips for cutting fulfilment costs while maintaining quality

There's no question that fulfilment costs can play an extraordinary role on your bottom line. Below are some recommendations to analyse if there's room for cost optimisation.

#1 Audit your eCommerce expenses

Some businesses allow their expenses to balloon without looking closely at where their money is going. So, what happens next? They end up overspending on unnecessary costs and cutting into their profits. A simple way to avoid this pitfall is to periodically audit your expenses. This will help identify points where you can save money, negotiate better rates with vendors, and catch errors and discrepancies that could be costing you.

#2 Negotiate rates with your chosen provider

When it comes to fulfilment, every penny counts. A good way to get lower costs is to compare rates from different providers. Once you've found a company with a competitive rate that still brings the level of service you need, proactively ask for fee negotiation. In most cases, they'll be more than willing to work with you to reduce fees in exchange for a longer-term commitment. Remember, the goal is to find a cost–service balance.

#3 Evaluate the different shipping options

You've done the hard work of building a great product and finding customers willing to pay for it. But there's one last hurdle to getting your product into your customers' hands: shipping. So, how do you evaluate shipping options to optimise costs? It may help to consider the type of product you're selling, where you're sending it to, and the delivery timeframe of it.

Is it fragile? Perishable? Valuable?

Are you shipping locally or internationally?

Do you offer same-day or next-day delivery?

The answers to these questions will help you narrow down your choices and find the right fit.

#4 Use a shared space warehouse

By sharing an eCommerce warehousing space with other retailers, you can take advantage of economies of scale and save money on other overhead costs, things such as rent, utilities, and labour. This is especially true if your in-house fulfilment is inefficient due to a lack of space.

#5 Automate processes where possible

Implementing technology that automates your eCommerce warehouse management and fulfilment system boosts efficiency while reducing labour costs. These processes include order management, inventory tracking, and shipping status, allowing merchants to avoid overstocking and unnecessary warehousing expenses. So, investing in tools like these can reduce your fulfilment costs and ensure that your customers always receive their orders on time.

#6 Make product descriptions clearer

This may seem like common sense, but it's incredible how many businesses fail to meet basic customer expectations. And sometimes, no matter how hard you try, there'll always be a certain percentage of customers who are dissatisfied with their purchase and want to send it back. But there are things we can do to reduce returns. One of these is to have super well-described product descriptions on your website or platform (Amazon, eBay, etc.).

Don't try to trick potential buyers into thinking your products are better than they are - be honest and upfront about what they can expect. If shoppers know exactly what they're buying, they're less likely to request a return and more likely to be satisfied with the overall experience.

#7 Do more of what's working right now

We know it may sound like counterintuitive advice. Obviously, you can't just sit back and do absolutely nothing. But if you review your fulfilment operation in detail, you may find that there are already some areas where you're performing well. So don't overlook the obvious - sometimes, an efficient way to save resources is to do more of what's working.

Let's say you're using a particular shipping method that's proven to be cost-effective. Why not increase the volume that you send using that method? Or, if you've found a supplier who consistently delivers quality products at a reasonable price, try ordering more from them.

Considerations when comparing 3PL fulfilment costs

Unsure if you're getting the best fulfilment pricing? You're not alone. We've all been there a few times. It's a bit complicated to know who to trust in the fulfilment world. That's why we put together this set of tips on how to compare 3PL fulfilment costs and pricing.

Make sure all fees and charges are fully transparent

Going with a third-party logistics (3PL) company for fulfilment services is a big decision. After all, these are the experts that will be handling your inventory, packing, shipping orders, and dealing with returns. So you want to make sure you're working with a reputable company.

A crucial element to look at when comparing 3PLs is their pricing structure. Make sure there are no hidden fees or confusing charges. You should be able to see a breakdown of all the costs involved, so there are no surprises down the road. A good 3PL will be upfront and transparent about pricing, so you can be confident you're getting the best possible value for your money.

Check that the storage fees match your eCommerce requirements

Too often, companies choose a 3PL based solely on cost, without considering all the factors that go into a fulfilment solution. As a result, they may find that the low upfront costs end up costing them more in the long run. For instance, if you have a high volume of orders, you should validate that the 3PL provider can offer economies of scale. On the other side, if you have a large inventory, you'll want to confirm that the 3PL can offer ample storage space.

Take a closer look at return charges, international orders, and packaging

Returns are a fact of life when selling online, and you don't want to be stuck with a provider who charges exorbitant fees for return shipping. Similarly, if you plan to sell internationally, you'll need a fulfilment centre with competitive rates for shipping to multiple countries. Many 3PL providers will charge extra for packaging materials and labour, while others include this in their base rate, so be sure to ask about this before making a decision.

Verify what shipping and customisation options are available

Some 3PLs may only offer ground shipping and basic customisation. Others may include air, express, and international deliveries, with more robust customisation alternatives, such as gift wrapping and personalised messages. So double-check what's available before selecting a 3PL, as this can affect fulfilment costs and customer experience.

Ask for any possible volume, and contract discounts

Most 3PL companies offer some type of discount for higher-volume customers and also for customers who sign long-term contracts. While the specifics vary from provider to provider, asking about any volume or contract special price that may be applied is fundamental. If you don't ask, you won't know if you're getting the best possible value for money.

Fund the fulfilment of your online shop with Bloom

Third-party logistic fulfilment costs can be a major expense for eCommerce businesses, and if you're not prepared, they can put a damper on your plans to scale. By understanding the ins and outs of fulfilment options, their associated costs, and their relative advantages and disadvantages, you can decide what's best for your online shop.

At Bloom, we're here to support your eCommerce business through every stage of growth. If at some point you ever need some capital to cover fulfilment costs smoothly and without any hiccups during the process, apply for a revenue-based loan. With a simple online form, you can be on your way to getting funds for inventory, cash flow, and marketing initiatives – in no time at all.

Written by

Sam founded his first startup back in 2010 and has since been building startups in the Content Marketing, SEO, eCommerce and SaaS verticals. Sam is a generalist with deep knowledge of lead generation and scaling acquisition and sales.